Introduction

The traditional and still most common method of obtaining water from groundwater sources in rural areas of the developing world is by means of hand-dug wells (WATERAID 2008).In contrast to surface water, groundwater is usually of higher water quality. Although technical equipment could support the construction of a dug well, excavation is mostly conducted manually as many rural regions offer cheap labour and lack adequate technical resources.

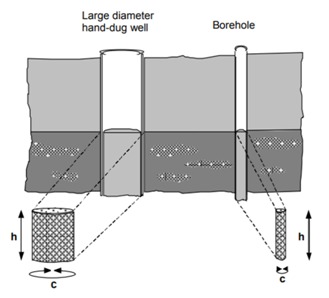

The basic principle is rather straightforward: With the prior knowledge that groundwater is present and close to the surface, a hole is dug until the groundwater level is reached. Inflowing groundwater is collected and can be extracted with the help of pumps or buckets. Depths of hand-dug wells range from shallow dug wells (about5 metres in depth) to deep dug wells (over 20 metres in depth). An excavation of about 1.5 metres in diameter provides adequate working space for the diggers and will allow a final internal diameter of about 1.2 metres after the well has been lined (WATERAID 2008). In some cultures, dug wells are more than 15 metres in diameter.

The performance of the well in terms of quantity is largely determined by the soil type (i.e. the porosity), by the diameter and depth of the well. Wells with a large diameter and depth expose a greater area for infiltration, and therefore provide fast recharge, e.g. an aquifer of 2 metres in depth and a well with 1.3 m diameter will expose 8.2 m2 for infiltration of water, while a 150 mm diameter drilled hole only exposes 1 m2 (COLLINS 2000).

Prerequisites

Before constructing a dug well, geological suitability of the area, acceptance within the community and the capability of operating and maintaining the system have to be assessed.

A thorough investigation of the area should be conducted in order to determine (see also exploring tools and understand your system):

- The type of source and soil (must allow safe excavation)

- Existence of an aquifer. Alternatively, dry riverbeds may provide a water source during dry-season (cf. NISSEN-PETERSEN 1997).

- The level of the groundwater (deep enough: protection against contamination of groundwater; but not too deep: safety of excavation, high effort)

- The quantity of available water (also in the perspective of a long-term perspective); the future recharge potential

- The quality of the water

- The range of technically feasible options for the construction (see COLLINS (2000) for a complete list of criteria).

Elements of a Dug Well

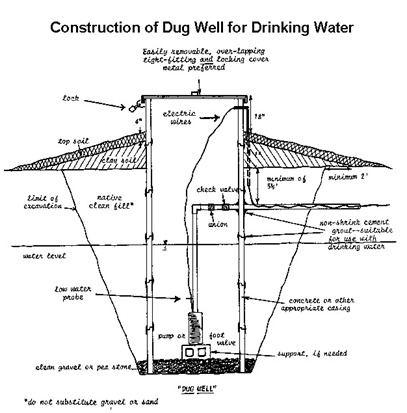

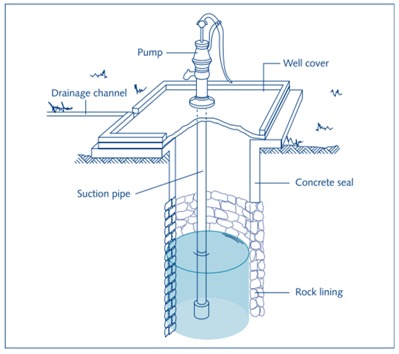

A dug well consists of three major components (COLLINS 2000):

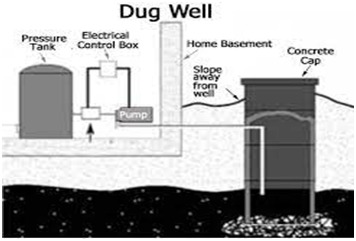

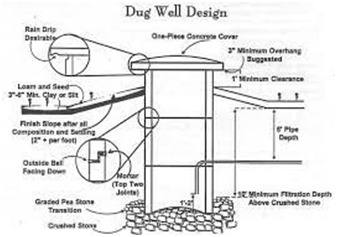

The well head: This is the part of the well, which is visible above the ground. It protects the well from contamination and generally consists of a well cover or apron, a concrete seal, a manhole (for access), a drainage channel and a pump.

- The well shaft: This is the section of the well between the head and the intake. It is made out of a strong, durable material, which can easily be kept clean.

- The intake: The walls of the intake are constructed in such a way as to allow water to pass from the aquifer into the well, thus creating a storage area, which can be accessed either by bucket or pump.

Construction

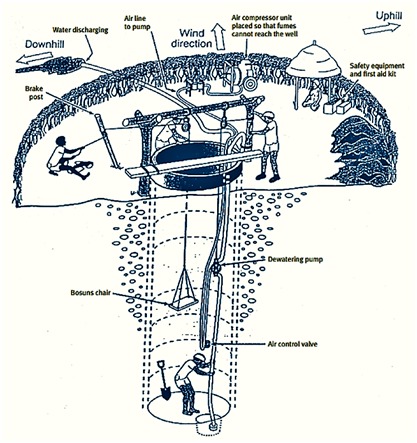

Under supervision, not skilled but physically capable workers are required in the whole construction process. During or after excavation, a permanent lining needs to be installed unless the well is constructed in consolidated ground (i.e. rock formations). The lining serves several purposes: During construction, it provides protection against caving and collapse and prevents crumbling ground from filling up the dug hole.

After completion of the well it retains the walls (SMET & WIJK 2002). Although a wide range of construction methods and materials (e.g. brick, stone, masonry, concrete cast in a shuttering inside the hole)can be used, most well programmes recommend the use of circular, precast concrete well “rings”. They can be produced on-site or in a local production centre. In very soft formations, the rings are sunk starting from the surface: digging from the inside of the ring, removing the material with a bucket and adding new rings as required. In harder, semi-consolidated formations, the rings can also be inlaid after having excavated the hole completely until the groundwater level (UNICEF 1999).

Regardless of the method that has been used to excavate the well to the water table, excavation below this level should never be attempted until the sides of the excavation have received the support of a permanent lining. Excavation below the water table should be carried out within precast concrete caisson rings of a smaller diameter than the rest of the well (WATERAID 2008). In most cases, a motorised pump is required to dewater the well to allow excavation below the water table; however, in some cases, efficient hand pumps can also be applied successfully (UNICEF 1999).

The section of the well penetrating the aquifer requires a lining with openings or perforations enabling the groundwater to flow into the well(SMET & WIJK2002). In formations with fine sand or silt particles, a filter at the bottom of the finished well is often necessary to prevent particles to enter and clog the well. Usually, the filter is made out of a layer of gravel and coarse sand or a porous concrete plug.

Operation and Maintenance

One of the key aspects in the long-term sustainability of any water supply system is the full and enthusiastic involvement of the community in all phases of the water supply process including operation, maintenance and management. The management of a water supply system is interdisciplinary in nature. Hence, operation and maintenance both include structural (i.e. technical) tasks and hygiene/health considerations.

Structural maintenance includes checking the apron for cracks, securing the inspection cover, improving the yield by deepening or removing infiltrated sand particles and the maintenance of the lifting device. Although no skilled worker is required to accomplish these tasks, regularity and accuracy is vital and has to be guaranteed.

Equally, securing hygienic operation is essential. This involves the protection and cleaning of the area (e.g. fencing and covering), checking water quality and disinfecting if necessary, monitoring the effects of withdrawal on environment and surrounding areas, and constantly educating water users in proper operation of the well and in the links of water sanitation and health.

Advantages

- High degree of involvement of the local community during the whole process

- Under supervision, no skilled workers are required

- Simple equipment sufficient for both construction and maintenance

- Low cost for construction and O&M

- Involvement of private sector possible (local well diggers)

- Use of locally available material

- Yield can be increased after construction, Reservoir included (large diameter)

- No substantial change of behaviour required, long construction phase supports the process of acceptance, Although favourable, no pumps are required to draw water

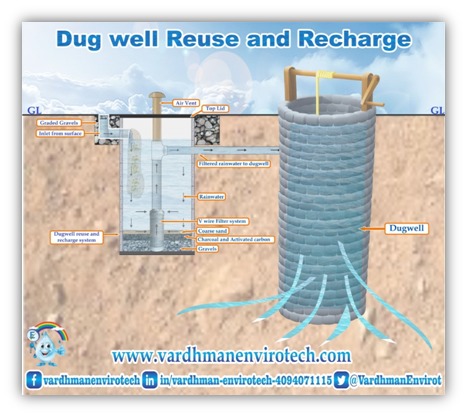

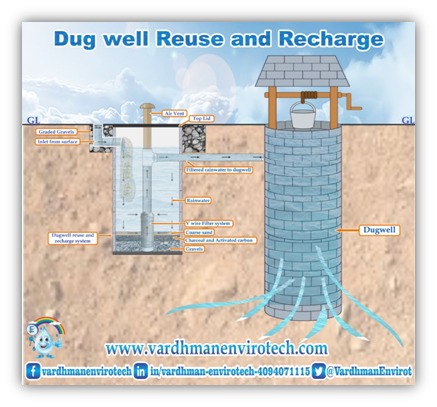

Dugwell Recharge

Dug well recharge is sensible option to augment groundwater level. Dug well recharge by using surface run off or roof run off increases efficiency of the well. Simple arrangement of local precast pipes with natural filter media and a micro filter is enough to divert surface runoff to dug well.

Existing and abandoned dug wells are to be utilized as recharge structure after cleaning and desilting the same. The recharge water is guided through a pipe from desilting chamber to the bottom of well or below the water level to avoid scouring of bottom and entrapment of air bubbles in the aquifer.

Especially surface run off needs extra care to filter our leaves, papers, plastics, silt, debris etc. before diverting in the dug well. Ready to use, filtration system that prevents major, medium and micro impurities flowing in dug well keeps the bottom of dug well clean without sediments. A green cover is suggest to prevent the evaporation losses from the open dug well.

Clean surface rainwater will fill the dug well and increase the water column that enables flushing out air in the unconfined zone of shallow aquifer. This creates space for sub surface water infiltration in the dug well, resulting in less recoup time for dug well.

Save nature ….. Save water ….. !!

Save the future ….!!!