Integral tank linkspan - TTS Group ASA

Integral tank linkspan - TTS Group ASA

Integral tank linkspan - TTS Group ASA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

POWER TO MOVE<br />

www.ttsgroup.com<br />

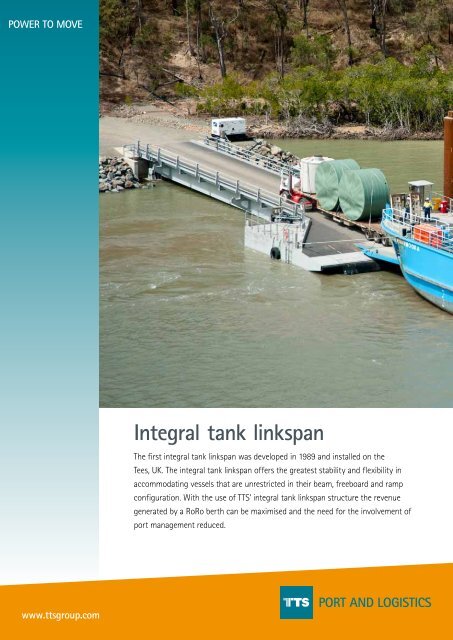

<strong>Integral</strong> <strong>tank</strong> <strong>linkspan</strong><br />

The first integral <strong>tank</strong> <strong>linkspan</strong> was developed in 1989 and installed on the<br />

Tees, UK. The integral <strong>tank</strong> <strong>linkspan</strong> offers the greatest stability and flexibility in<br />

accommodating vessels that are unrestricted in their beam, freeboard and ramp<br />

configuration. With the use of <strong>TTS</strong>’ integral <strong>tank</strong> <strong>linkspan</strong> structure the revenue<br />

generated by a RoRo berth can be maximised and the need for the involvement of<br />

port management reduced.<br />

PORT AND LOGISTICS

INTEGRAL TANK LINKSPAN<br />

Both the gradient and the<br />

transition angles can be<br />

specifically designed for any<br />

location, enabling the structure<br />

to be tailored to significantly<br />

reduce turnaround times. The<br />

integral <strong>tank</strong> <strong>linkspan</strong>, with no<br />

permanent support structure or<br />

portal at its outer end provides<br />

a clear, safe smooth transition<br />

between quay and ship.<br />

Many integral <strong>tank</strong> <strong>linkspan</strong>s<br />

have been installed around<br />

the world, <strong>TTS</strong> having<br />

designed and supplied a good<br />

proportion of these, all of<br />

which meet the customers’<br />

required performance and<br />

safety criteria.<br />

The integral <strong>tank</strong> <strong>linkspan</strong><br />

is supported at its widened<br />

outer end by a floating section<br />

that is part of the bridge<br />

structure. This section is deep<br />

enough to float at a level to<br />

match the freeboard of the<br />

vessel using it. The level is<br />

adjusted by a simple but rapid<br />

ballast system. The floating<br />

<strong>TTS</strong> Port Equipment AB<br />

Kämpegatan 3<br />

SE-411 04 Göteborg<br />

Sweden<br />

Tel: +46 31 725 79 00<br />

Fax: +46 31 725 78 04<br />

info@tts-port.se<br />

www.ttsgroup.com<br />

<strong>TTS</strong> Handling Systems AS<br />

Holterkollvn 6,<br />

NO-1441 Drøbak<br />

Norway<br />

Tel: +47 64 90 79 10<br />

Fax: +47 64 93 16 63<br />

info@tts-hs.no<br />

<strong>TTS</strong> Liftec Oy<br />

Sorkkalantie 394<br />

33980 Pirkkala<br />

Finland<br />

Tel: +358 3 3140 1400<br />

Fax: +358 3 3140 1444<br />

sales@tts-liftec.fi<br />

section also has a large<br />

water-plane area that limits<br />

the immersion due to traffic<br />

load to within manageable<br />

proportions.<br />

The increase in the width of<br />

the outer end also creates a<br />

large landing area onto which<br />

ship’s ramps, unrestricted<br />

in width or length, may be<br />

lowered. In addition to being<br />

able to accept all RoRo vessels<br />

regardless of their freeboard,<br />

beam or ramp size, the<br />

passage of vehicles is much<br />

smoother than with other<br />

floating types. There are only<br />

two managed articulated<br />

junctions at the hinge and<br />

at the ship’s ramp allowing<br />

the transition angles to be<br />

optimised.<br />

<strong>Integral</strong> <strong>tank</strong> <strong>linkspan</strong>s can<br />

be supplied with upper decks<br />

and in skewed configuration.<br />

Extendable flaps may also<br />

be supplied to allow use by<br />

female ships (those without<br />

ramps). These flaps stow flush<br />

with the deck, so as not to<br />

interfere with the ramp of any<br />

other ship using the berth.<br />

PORT AND LOGISTICS

![2012.MasterPresentation_final [Compatibility Mode] - TTS Group ASA](https://img.yumpu.com/4612021/1/190x146/2012masterpresentation-final-compatibility-mode-tts-group-asa.jpg?quality=85)